Updated:

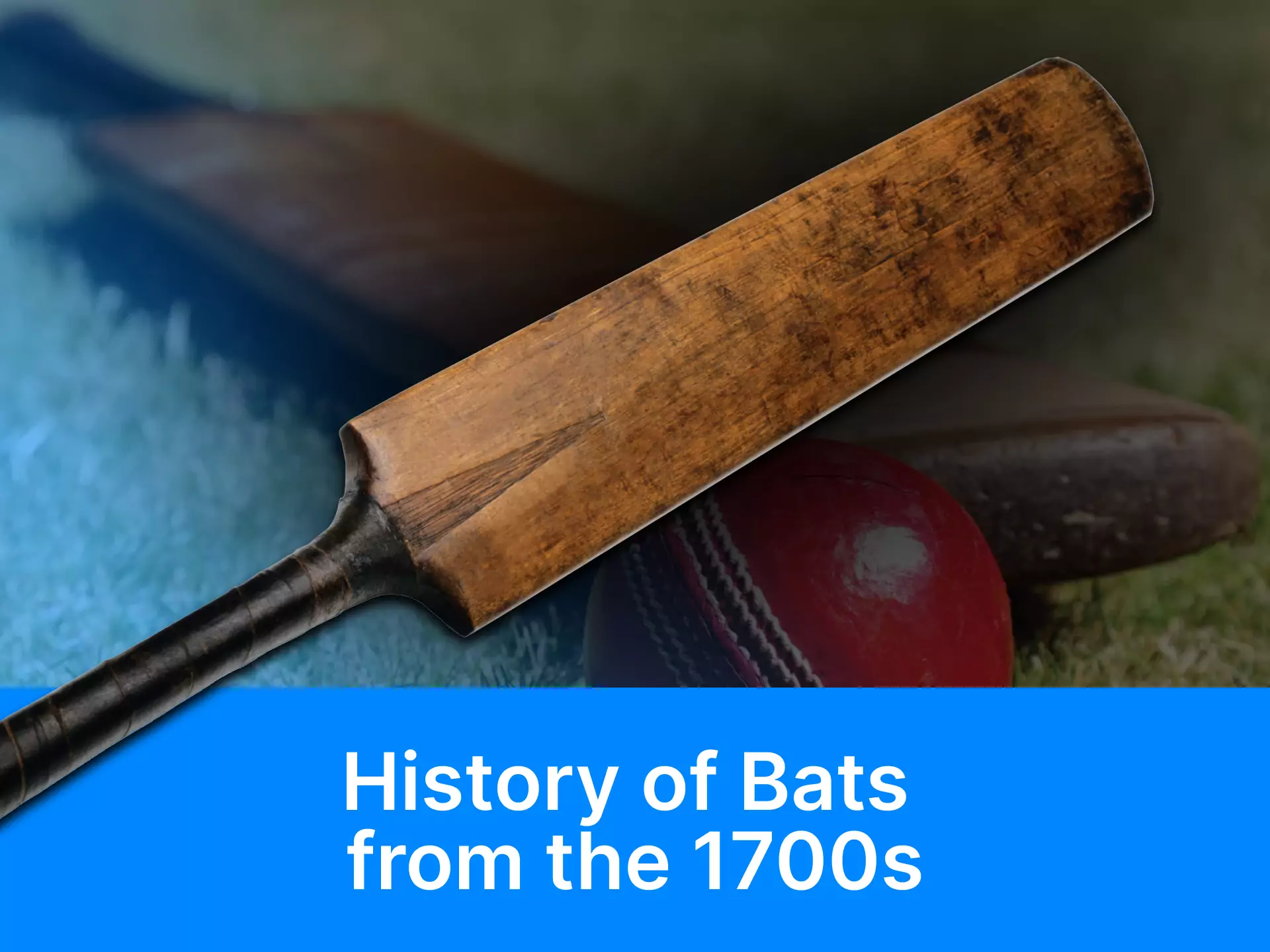

History of Cricket Bats from the 1700s

The cricket bat has evolved significantly since it first came into use in the 1700s. In the early days of the sport, players used a variety of different implements to hit the ball, including their hands and even sticks. However, as the sport grew in popularity and became more organized, the need for a specialized tool for hitting the ball became apparent. Willow was the most common material used in the production of the first cricket bats.

- These early bats were relatively simple in design, with a straight handle and a flat blade. The flat blade made it difficult to hit the ball with precision, and the straight handle provided little leverage for power. As the sport continued to develop, so too did the design of the cricket bat. In the late 1700s, the shape of the blade began to change, with the addition of a curved shape to the blade.

- This new design made it easier for players to hit the ball with precision and power. Additionally, the handle of the bat was also redesigned to provide more leverage for the player. In addition to the changes in the design of the bat, the materials used to make the bat also changed. While willow remained the most popular wood for making cricket bats, other materials such as ash, hickory and even bamboo were also used.

- After the initial period of evolution, wood began to be manufactured in a more standardized manner. The remains of the plant were peeled and shaped into bat blanks. The trunks were split along their length, the bark removed and the surfaces flattened to create a more uniform wall thickness.

Typically, blanks for finished bats have a wall thickness of approximately 2 mm. Some bats were also made from ash. Manufacturers discovered that it was possible to make thick pieces of shoe last which could be vulcanized into bats. In either case, the finished article was sent to a professional bat maker who would then craft it into a finely finished bat. The use of machinery allowed firms to produce high volumes of good-quality bats at a reduced cost.

Cricket Bats in the 1850s

Now, when the laws on bowling were changed from underarm to overarm in 1864, batsmen had to develop new playing styles to adapt to the new laws. Making the handling lighter leads to a danger of explosion with splinters flying out of the end of the wood. To try and get around this, they made a handle out of cork which gave way more easily without exploding back in your hand.

- In 1880, another step was taken when crutches were added beneath the handle. In the 1840s and on, manufacturers began to make bats with separate handles joined by splicing, as a one-piece affair was found to be liable to breakage. Modern cricket bats are still made from the same materials, but there has been a very different kind of transition.

- Today’s bats are designed to cope not only with heavier balls travelling much faster but also with field settings that provide protection to both batsmen and wicketkeepers, not to mention pitches prepared in different ways for different purposes. The use of two new kinds of synthetic material and computer technology have changed bat design even more profoundly than the introduction of round-arm bowling did in the 1820s. Precisely, The 1800s saw a continued evolution of the cricket bat.

- The blade of the bat became even more curved, and the handle was redesigned to provide even more leverage for the player. Additionally, the use of new technologies such as steam-bending and machine-made blades allowed for the mass production of cricket bats, making them more readily available to players of all skill levels.

One can clearly say that bats through the ages have always been central to cricket. They have also undergone several changes over the years, undergoing major transformations in response to technological advancements and innovations. These changes have helped batsmen exert varied styles of play despite playing with the same equipment as their predecessors, a phenomenon not exclusive to cricket by any means.

Cricket Bats in the 1970s

Bat construction became a controversial issue in the 1970s as the size of cricket bats changed from that of a machete to that of a meat cleaver. In 1999, John Buchanan, the coach of Australia who had just returned after managing South Africa’s cricket team, suggested that there should be limitations on bat size and he recommended the edges to be about 3.25 cm thick for safety reasons.

- During that period, ICC’s Cricket Committee made restrictions on bat sizes and shapes with the aims of increasing average match time, reducing wide balls and increasing parity between bat and ball. The maximum width and depth of the bat were limited to 108 mm and 67 mm respectively while its length could not exceed 38 inches.

- The playing area also had to be notified as a ‘controlled area’ where no artificial substance would be used by batsmen under any circumstances. However, some of these restrictions were later relaxed. Thus, today cricket batters can use bats up to 40 inches long, and are allowed to have edged up to 45 mm in width and padding up to 25mm thick within their bats.

- Now, the face of the bat has a raised equator with concave or moulded sides. It is generally made up of two pieces of wood glued together at the edges, as opposed to being made of a single piece. The lighter the weight, the greater chance it has for speed and power on impact and since the barrel section contributes most to these qualities, it is common to see big-hitting bats made that way.

- In the 1970s, traditional willow wood was still the most popular material used to make cricket bats. However, new materials such as aluminium and composite materials began to be used to make cricket bats. Aluminium bats were introduced in the 1970s as a cheaper alternative to willow wood and were more durable. They were also much lighter than wooden bats, allowing for more control and power when hitting the ball. However, aluminium bats were not approved for use in professional cricket because they were considered to have an unfair advantage over traditional wooden bats.

- The 1970s also saw the introduction of composite materials in the manufacturing of cricket bats. These materials were a combination of different materials such as graphite, fibreglass, and Kevlar. Composite materials were more durable, and lightweight than wooden bats and provided a better balance of power and control when hitting the ball. They were also more resistant to moisture and weather changes, which made them more suitable for use in one-day cricket.

The introduction of new shapes and sizes of bats also allowed batsmen to have a bat that was perfectly suited to their playing style, which helped to improve their performance on the field. The 1970s era also marked the beginning of the trend of custom-made bats which is still prevalent in the present era. The cricket bat has come a long way since its early days and continues to evolve to meet the changing needs of the modern game.

Cricket Bats in the 2000s

The depth of the bat has remained in constant debate since the size and weight are very crucial elements for batsmen to generate more power, maintain balance and also provide more durability. A batsman who is used to playing with a nine-ounce bat can easily transition to a bat which is five ounces lighter as both these pieces of equipment have the same feel.

- Of course, a greater mass will result in a bigger energy transfer and faster ball speed. But what happens if manufacturers produce a 30-ounce bat that has the same weight distribution as a 22-ounce specimen? The only difference will be that there will be fewer vibrations on impact, resulting in greater comfort for the batsman. However, there is no reason why cricket authorities should restrict the dimensions of the bat in order to let players maximize their ability.

- However, in the 2000s, the MCC led by Former England captain Mike Brearley introduced some more restrictions on the bat’s size. Now, with these rules, the depth of the bat will be increased and the weight will be reduced so as to give a fair chance to everyone out there.

- In the 2000s, the cricket bat market was highly competitive, with many brands vying for the attention of players at all levels. Some of the most popular brands include Gray-Nicolls, Kookaburra, and Adidas. Each of these brands has its own unique offerings, with Gray-Nicolls being known for its traditional design and quality, Kookaburra for its innovative designs and Adidas for its high-quality materials and technology.

- Moreover, the cricket bat market is not only restricted to professional players but also caters to amateur players, who are looking for an affordable yet good quality bat. With the increased popularity of the sport, the market has also seen a rise in the number of new players, which has led to an increase in demand for low-cost cricket bats. Many manufacturers now offer entry-level bats that are more affordable, but still, provide good performance.

However, the cricket bat industry is not without its challenges. One of the biggest issues is the sustainability of the materials used in the construction of cricket bats. The majority of cricket bats are made from willow wood, which is a non-renewable resource. As a result, many manufacturers are exploring alternative materials such as bamboo and composite materials to reduce the environmental impact of their bats.

The Current Condition of Cricket Bats

Cricket bats have evolved over a period of time, with many changes to their features, materials and shape. But basically, the concept of the cricket bat has remained the same. It is intended to produce more power when striking the ball. The kind of wood used for making cricket bats has undergone a change. Most often than not, it is made up of a Willow tree, which includes varieties like white willow, black willow and osier. Cricket bats are also made from other materials like aluminium and carbon fibre. Although there are no specific rules governing the making of cricket bats. Generally, a bat can be thicker at the toe than thinner at the edges in order to give it more body weight and power. But in the early days of cricket, a thin willow stick was used to hit a leather ball which was considered to be the crude version of today’s hardball cricket. However, currently, the condition of bats has become bolder and hence the batters are more effective. Moreover, the bats have gone slim and hence it is easier for the batters to hit long sixes. Clearly, Cricket bats come to the rescue of cricketers when they are completely out of ideas. A well-placed shot on the ground or a six over the fence can make all the difference in a cricket match. Since time immemorial, bats have been part and parcel of cricket. From being made of willow for well over a century, bats have undergone significant changes thanks to advancements in technology and innovations. Surely, the players like David Warner, Chris Gayle, Jos Buttler and other hard hitters have made use of these bats and have been the nightmare of the bowlers. But as the game progresses, the members of the International Cricket Council will look to have equal competition between the bat and ball.

Latest Posts

Cricket Competition Formats: Full Guide 2023

Overview of cricket competition formats: Test Matches, ODI, T20. Learn more about cricket competition formats now.

Women's Cricket: History, Records and Legendary Players

A detailed history of women's cricket. Learn about the records and legendary players in women's cricket!

Cricket Rules: Full Guide [year]

A complete guide to the rules of cricket. Learn the rules of the game, key terms, and the rules of scorekeeping in cricket matches.

Cricket Player's Gear and Equipment – Full Guide [year]

A complete guide to equipment in cricket. Find out the list of cricketers' equipment from the best teams in the world!